Methods for avoiding dehydration sieve failure

2016-08-31

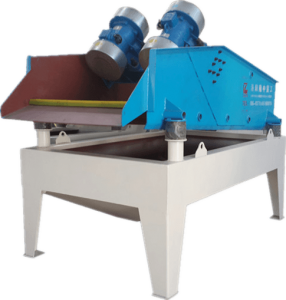

Dehydration sieve in the process of mining metallurgy and other processes are more frequent usage, then how to carry out routine maintenance to avoid failure?

First of all, carry out regular testing of dehydration sieve, the failure of timely and effective to solve the problems. You should replace the triangular belt regularly, which generally mounted on belt pulley. You know a long time with the triangle belt is worn, the friction decreases, there will be a slip phenomenon. The screen is vulnerable to dewatering screen, regular replacement of grinding mesh to improve production efficiency. In addition, it is very necessary to replace the broken bolt in time, drive the bearing and reduce the vibration spring.

Secondly, the dehydration sieve side to prevent stress concentration, should not be welded here, LZZG dewatering screen using the overall bending box, improve the overall strength, also improve the appearance of the whole dehydration sieve. Replace the screen below the cracking beam in time, repair the sieve box side cracks timely, to improve the strength of reinforcement.

Message