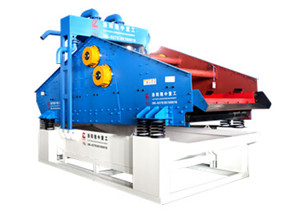

No.6 fine sand recycle system

In the past few years, we improve core technical, select new processing methods and absorb different sites working situation, and successfully make No.6 sand recycling system as our LZZG brand. It is also called as “dewatering type sand recycling system”.

In the past few years, we improve core technical, select new processing methods and absorb different sites working situation, and successfully make No.6 sand recycling system as our LZZG brand. It is also called as “dewatering type sand recycling system”.

Working principle

About No.6 sand recycling system, we still choose polyurethane screen as its main screening part, and add recycling part on TS dewatering screen.

Sand after sand washer is fed onto polyurethane screen for dewatering, waste sand water through steel chute or rubber pipe in water tank and extracted by slurry pump into high pressure sediment separator, fine sand 0.16-3mm is sprayed onto polyurethane screen also for de-watering, the waste water is back to return box and flowing out.

Features

- 1. Dewatering type sand recycling system, sand grading is better.

- 2. Recycling 0.16-3mm fine sand.

- 3. Recycling rate reaches above 95%.

- 4. The water content of final sand is within 12%-15%.

- 5. Compact structure and install easily.

Specification

| Model | Feeding Size (mm) | Capacity (t/h) | Screen Panel (mm) | Hydrocyclone (mm) | Power (kw) | Overall Size (mm) |

| LZ1530-65 | ≤10 | 30-60 | 1500X3000 | 300X2 | 36 | 3300X5250X3000 |

| LZ1842-75 | ≤10 | 40-80 | 1800X4200 | 350X2 | 48 | 4600X5560X3520 |

| LZ1842J-100 | ≤10 | 60-100 | 1800X4200 | 250X4 | 59 | 4600X5560X3520 |

| LZ2442J-120 | ≤10 | 100-150 | 2400X4200 | 300X4 | 82 | 4600X6250X3600 |

| LZ3442J-140 | ≤10 | 100-150 | 2400X4800 | 350X4 | 96 | 4600X6250X3600 |

| LZ3048J-140 | ≤10 | 120-200 | 3000X4800 | 350X4 | 104 | 5400X7000X4200 |

| LZ3060J-180 | ≤10 | 120-200 | 3000X6000 | 300X6 | 127 | 6600X7000X4200 |

| LZ3660J-180 | ≤10 | 150-250 | 3600X6000 | 300X6 | 134 | 6600X7000X4800 |

Message